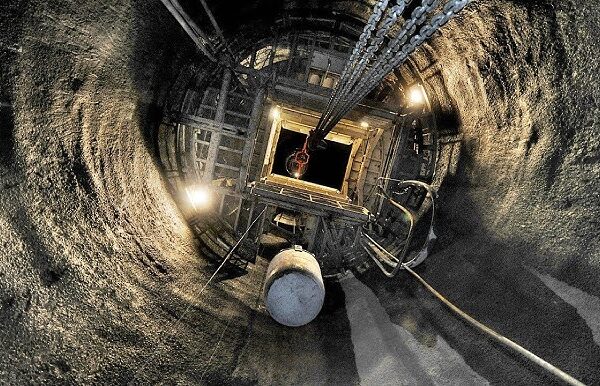

Horizontal Tunnel Excavation

Horizontal tunnel excavation refers to the process of creating tunnels that run horizontally beneath the surface of the earth. This technique is crucial for various infrastructure projects, including transportation systems (like subways and railways), utilities (sewer and water lines), and other underground constructions. Unlike traditional vertical excavation methods, horizontal tunneling minimizes surface disruption and can be used in urban areas or sensitive environments where maintaining the suprafacial landscape is essential.

Methods of Horizontal Tunnel Excavation

Several methods are employed for horizontal tunnel excavation, each suited to different conditions and requirements:

- Boring Machines:

- Tunnel Boring Machines (TBM): These large machines are designed specifically to excavate tunnels with a circular cross-section. They use a rotating cutter head that grinds through soil, rock, or mixed ground conditions while simultaneously installing lining segments to support the tunnel walls.

- Microtunneling: A smaller-scale version often utilized for utility installations in confined spaces. This method employs remote-controlled boring machines equipped with cutting heads that can work through soft soils or rocks.

- Ditch Witch Systems:

- Often used for smaller diameter pipelines, these trenchless technologies allow underground cable installation without significant surface disturbance by utilizing horizontal directional drilling techniques.

- Auger Boring:

- In this method, a rotating auger bit creates a hole underground as it advances forward while removing spoil back up to the surface through an enclosed casing.

- Cut-and-Cover Tunneling:

- A less sophisticated but effective approach involves digging an open trench along which concrete walls are built before covering it back over again once construction finishes; thus forming tunnels below grade level afterward when completed!

- Jetting Techniques: In some applications like pipeline installations where soil conditions allow—water jets may be employed alongside augers enabling faster penetration through softer materials without excessive vibrational impact caused by traditional drilling processes!

Applications of Horizontal Tunnel Excavation

Horizontal tunneling has numerous applications across various sectors:

- Transportation Infrastructure: Construction of metro lines, road tunnels under rivers/mountains.

- Utility Installation: Laying down sewer systems or water supply pipes while avoiding street-level disruptions.

- Mining Operations: Accessing mineral deposits efficiently using advanced techniques adapted from civil engineering principles allowing precise extraction locations!

- Geotechnical Investigations & Environmental Remediation Projects: Monitoring subsurface conditions while implementing solutions mitigate contamination impacts effectively!

Challenges in Horizontal Tunnel Excavation

While there are many advantages to horizontal tunnel excavation, several challenges need consideration:

- Ground Conditions: Variability in geology can affect machinery performance; harder rock formations may require specialized equipment extending timelines/costs accordingly.

- Water Management: Handling groundwater inflow becomes critical during tunneling operations necessitating appropriate drainage/mitigation strategies preventing flooding issues throughout project lifecycle!

- Noise & Vibration Control Measures must also be enacted especially near residential neighborhoods ensuring compliance regulations adhered strictly safeguarding public interests at all times.

Horizontal tunnel excavation serves as an indispensable component within contemporary infrastructure development offering unique advantages across diverse applications—from transportation networks utilities access environmental management initiatives alike—all whilst enhancing efficiency sustainability minimizing impacts on surrounding areas effectively showcasing ingenuity modern engineering principles today!

Our Valuable Works With the Clients

Our team is dedicated to delivering exceptional value through close collaboration with our clients. We prioritize understanding their needs and providing tailored solutions for success.

Frequently Asked Questions

What is horizontal tunnel excavation?

What are the main methods used in horizontal tunnel excavation?

Tunnel Boring Machines (TBM)

Microtunneling

Ditch Witch Systems

Auger Boring

Cut-and-Cover Tunneling

Jetting Techniques

What are the advantages of using horizontal tunnel excavation?

How does horizontal tunneling minimize surface disruption?

In what applications is horizontal tunnel excavation commonly used?

Transportation infrastructure (metro lines and road tunnels)

Utility installations (water supply pipelines and sewer systems)

Mining operations

Environmental remediation

Geotechnical investigations

Are there any challenges associated with horizontal tunnel excavation?

Is vertical clearance required when performing this type of excavation?

How does one ensure safety during a tunneling project?

Can existing underground utilities interfere with tunneling projects?

How long does it usually take to complete a horizontal tunnel excavation project?

Gallery

Reach Out for Expert Horizontal Tunnel Excavation Service Solutions